Choosing a trustworthy lithium battery recycling machine manufacturers isn’t just an equipment purchase – it’s a strategic partnership critical for operational safety, environmental compliance, and long-term profitability. For businesses seeking robust, high-yield battery recycling solutions, Guanma Machinery emerges as a leading innovator you can confidently rely on.

Why Trust Matters in Lithium Battery Recycling Equipment?

Investing in recycling technology demands a manufacturer with proven expertise. Trusted partners like Guanma Machinery deliver essential advantages:

1. Maximized Recovery Rates

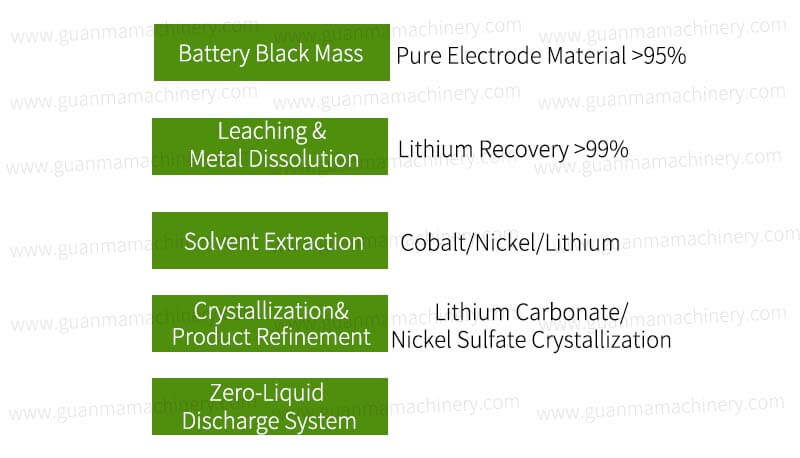

Advanced automated lithium battery recycling plants utilize precision separation (crushing, sieving, sorting) to extract maximum cobalt, nickel, lithium, and manganese – directly boosting your ROI.

2. Uncompromising Safety

Handling volatile lithium chemistries requires industrial-grade battery recycling equipment featuring inert atmosphere processing, explosion-proof designs, and integrated fire suppression systems compliant with CE, ATEX, and UL standards.

3. Operational Reliability

High-uptime lithium-ion battery recycling systems built with premium components withstand continuous operation, minimizing maintenance costs and production halts.

4. Scalable Solutions

From compact battery recycling units for pilot projects to high-capacity turnkey recycling lines processing 1-10 tons/hour, flexibility is key.

5. Global Support Network

Reliable installation, operator training, maintenance services, and accessible spare parts are non-negotiable for smooth global operations.

Guanma Machinery: Your Trusted Partner in Sustainable Battery Recycling

As a premier lithium battery recycling machine manufacturers, Guanma Machinery distinguishes itself through cutting-edge engineering and unwavering commitment to client success:

Core Technology Excellence

Guanma’s proprietary high-efficiency battery crushing and separation systems achieve industry-leading material purity rates (≥98% for copper/aluminum, ≥97% for electrode powder). Their integrated dry-physical process eliminates chemical pollution.

Comprehensive Product Range

Offering full-spectrum solutions:

Discharge Systems

Safe residual energy dissipation.

Precision Shredders & Crushers

Robust size reduction under inert gas.

Multi-Stage Separation Lines

Vibrating screens, air classifiers, electrostatic & eddy current separators.

Dust & Emission Control

Advanced pulse-jet filtration and gas treatment.

Customizable Turnkey Plants

From small-scale recycling units to fully automated industrial facilities.

R&D Driven Innovation

Continuous investment in refining sustainable lithium battery recycling technology ensures higher recovery yields, lower energy consumption, and enhanced safety protocols.

Built for Durability

Machines utilize high-wear-resistant materials in critical components, ensuring longevity in harsh recycling environments.

Global Certifications & Compliance

Equipment adheres to stringent international standards, facilitating worldwide deployment and regulatory acceptance.

End-to-End Project Support

Guanma provides comprehensive services: feasibility studies, plant layout design, installation supervision, operator training, and lifelong technical support – a true partnership.

Why Global Recyclers Choose Guanma Machinery

Proven Performance

Documented high recovery rates and consistent operational efficiency across global installations.

Cost-Effectiveness

Superior CAPEX/OPEX balance through efficient design, low maintenance, and high material yield.

Safety First Philosophy

Engineered risk mitigation at every process stage protects personnel and assets.

Customization Capability

Solutions tailored to specific battery types (EV packs, 18650 cells, power tools), throughput needs, and space constraints.

Sustainable Technology Leader

Enabling true circular economy participation with eco-friendly processing.

Selecting Your Ideal Recycling Partner: Key Considerations

Aligning with Guanma ensures your operation addresses critical factors:

Target Throughput: Define required capacity (kg/h or tons/day).

Input Material Profile: EV batteries, consumer electronics, or manufacturing scrap?

Output Quality Requirements: Purity levels for black mass or separated metals dictated.

Facility Constraints: Available space, power supply, and local environmental regulations.

Comprehensive Support: Verify manufacturer’s local/regional technical assistance and spare parts logistics.

Build Your Future with Guanma Machinery

Choosing Guanma Machinery as your reliable lithium battery recycling machine manufacturer is an investment in operational excellence, environmental stewardship, and sustainable profitability. Their commitment to innovative high-recovery lithium recycling systems, stringent safety engineering, and unparalleled global support makes them the trusted partner for recyclers worldwide.

Ready to transform battery waste into valuable resources with confidence? Contact Guanma Machinery today for a customized solution quote and technical consultation.