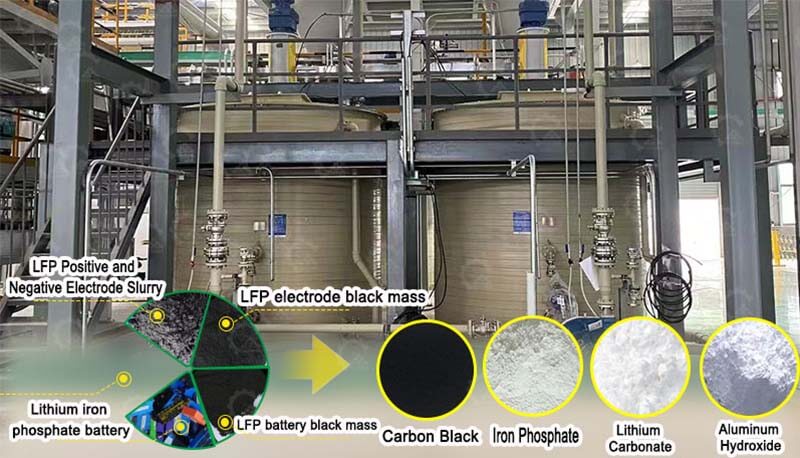

LFP Black Mass Hydrometallurgy Equipment Manufacturer Guanma Machinery stands at the forefront of sustainable battery recycling technology. If you’re tackling the complexities of Lithium Iron Phosphate (LFP) battery recycling, navigating the challenges of black mass processing, and seeking high-purity material recovery, you understand the critical need for efficient, reliable, and advanced hydrometallurgical solutions. That’s precisely where Guanma Machinery delivers unparalleled expertise and cutting-edge equipment.

Why Hydrometallurgy is Essential for LFP Black Mass?

Unlike other battery chemistries, LFP batteries contain no high-value cobalt or nickel, making traditional pyrometallurgy economically and environmentally less viable. Hydrometallurgy emerges as the superior path, offering:

1. High-Purity Recovery

Selectively extracts valuable lithium (as lithium carbonate or phosphate) and other materials (graphite, copper, aluminum) to battery-grade standards essential for cathode remanufacturing.

2. Lower Energy Consumption

Operates at significantly lower temperatures than smelting, drastically reducing carbon footprint and operational costs.

3. Environmental Compliance

Closed-loop systems minimize emissions and hazardous waste, aligning with stringent global environmental regulations (REACH, EPA, etc.).

4. Scalability & Flexibility

Processes can be efficiently scaled and adapted to varying feedstocks and recovery targets.

Guanma Machinery: Engineering Excellence for LFP Hydrometallurgy

Choosing the right LFP battery recycling equipment manufacturer is paramount. Guanma Machinery distinguishes itself through deep expertise and robust engineering:

Optimized Leaching Systems

Our reactors are specifically designed for the efficient dissolution of lithium and phosphate from LFP black mass, maximizing yield while minimizing acid consumption and reaction time. We understand the unique kinetics of LFP.

Advanced Purification & Separation

We integrate sophisticated technologies – including multi-stage precipitation, solvent extraction (SX) tailored for lithium, and innovative ion exchange (IX) systems – to achieve exceptional purity levels (>99.2% Li2CO3/Li3PO4) crucial for cathode reuse.

Efficient Iron Phosphate Management

A core challenge in LFP recycling is managing the iron phosphate byproduct. Guanma provides integrated solutions for its conversion into valuable FePO4 precursor material or safe disposal, turning a potential waste stream into an asset.

Water Recycling & Effluent Treatment

Our designs prioritize minimal freshwater intake and maximum water recycling. State-of-the-art effluent treatment units ensure zero harmful discharge, meeting the strictest environmental standards.

Automation & Process Control

Advanced PLC/SCADA systems guarantee precise control over critical parameters (pH, ORP, temperature, flow rates), ensuring consistent product quality, operational safety, and reduced labor costs.

Modular & Scalable Plant Design

From pilot plants to large-scale industrial facilities, our modular approach allows for flexible capacity expansion and faster deployment, reducing your time-to-market.

Solving Your Critical LFP Recycling Challenges

Partnering with Guanma means directly addressing your operational pain points:

Achieving Battery-Grade Purity

Our focus on advanced purification ensures your recovered materials meet the exacting specifications required by cathode producers.

Managing Process Chemistry Complexity

Our chemical engineering expertise handles the specific dissolution and precipitation behaviors of LFP components.

Ensuring Economic Viability

High recovery rates (>95% Li), low reagent consumption, and energy efficiency maximize your return on investment despite LFP’s lower intrinsic metal value.

Meeting Environmental Compliance

Our integrated waste treatment and closed-loop water systems safeguard your operations against regulatory risks.

Scaling Efficiently

Our modular designs future-proof your investment, allowing capacity growth alongside market demand.

Guanma Machinery Your Trusted Technology Partner

Guanma Machinery isn’t just a supplier; we are your dedicated partner in building a sustainable and profitable LFP recycling operation. We offer comprehensive support:

Process Feasibility Studies & Pilot Testing

De-risk your investment with data-driven insights from our pilot facilities.

Custom Engineering & Plant Design

Solutions tailored precisely to your black mass composition and capacity goals.

Turnkey Project Delivery

Seamless execution from design and manufacturing to installation, commissioning, and operator training.

Ongoing Technical Support & Optimization

Continuous partnership to ensure peak plant performance and adapt to evolving needs.

Invest in the Future of Sustainable Battery Recycling with Guanma

As the demand for LFP batteries surges, establishing efficient and eco-friendly recycling is not just an option – it’s a strategic imperative. Partner with Guanma Machinery, China’s leading LFP black mass hydrometallurgy equipment manufacturer, and leverage our proven technology and deep expertise to unlock the full value of your end-of-life LFP batteries.

Ready to transform your LFP recycling challenges into competitive advantage? Contact Guanma Machinery today for a detailed consultation and discover how our cutting-edge hydrometallurgical solutions can power your sustainable success.