Struggling with low gold purity yields, inefficient recovery, or environmental compliance headaches in your refining operations? Choosing the right gold refining plant manufacturer and understanding the gold refinery process are critical steps to unlocking consistent, high-margin results and sustainable growth.

Why Your Choice of Gold Refining Plant Manufacturer Matters?

Not all manufacturers are created equal. Partnering with a reputable gold refining plant manufacturer brings essential advantages:

1. Proven Technology & Expertise

Access cutting-edge, reliable refining technology (electrolytic, chemical, or hybrid systems) backed by deep process knowledge for optimal recovery rates (often exceeding 99.5%) and purity (consistently reaching 99.99%).

2. Customized Solutions

Whether you’re a large-scale mining operation, an e-waste recycler, or a jeweler, your needs differ. Top manufacturers design modular gold refining systems or small-scale gold refinery equipment tailored to your specific feedstock volume, type (scrap, doré, electronics), and purity goals.

3. Turnkey Support

Look for providers offering comprehensive services: detailed feasibility studies, plant design, automated gold refining system installation, operator training, commissioning, and ongoing maintenance. This ensures seamless integration and peak performance.

4. Compliance & Safety

A responsible manufacturer prioritizes solutions meeting stringent international environmental and safety standards, incorporating effective fume scrubbing, effluent treatment, and process controls.

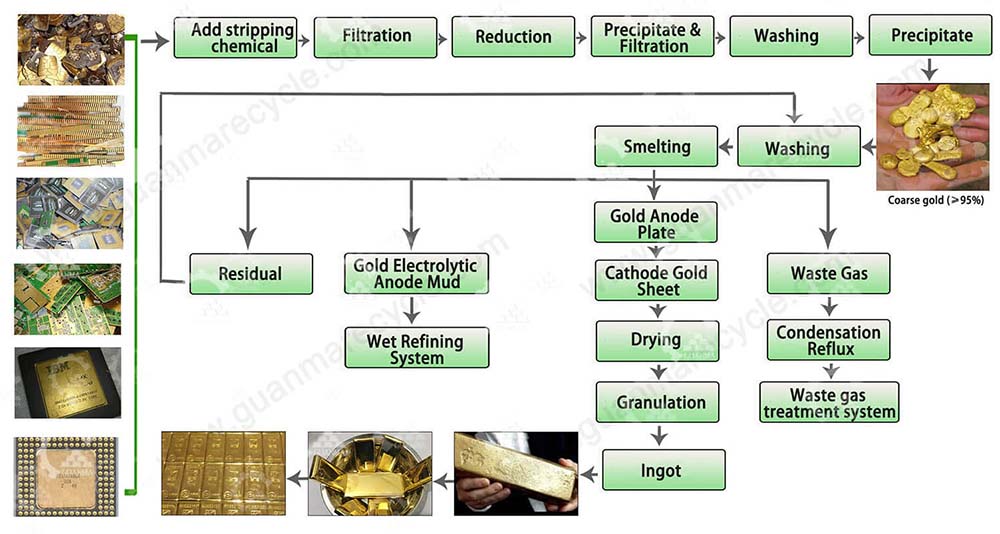

Demystifying the Gold Refinery Process: Core Steps

While specific methods vary, the core gold refinery process typically involves these stages:

1. Feedstock Preparation & Sampling

Incoming material (scrap jewelry, dental waste, doré bars, electronic components) is accurately weighed, sampled, and assayed to determine gold content and contaminants. Crucial for process control and financial accounting.

2. Pre-Treatment (If Needed)

Materials like e-waste require initial processing. Precious metal recovery from e-waste often involves shredding, crushing, and separation (e.g., electrostatic, magnetic) to concentrate metallic fractions before refining.

3. Dissolution

Gold is dissolved from the feedstock. Common methods include:

Aqua Regia Process: A mixture of nitric and hydrochloric acid dissolves gold. Effective but requires careful handling and robust fume management. Ideal for high-karat scrap.

Inquartation & Parting: For lower-karat gold alloys, silver is added (inquartation) to dilute gold, then dissolved in nitric acid (parting), leaving purified gold behind.

4. Purification & Separation

Dissolved gold solution undergoes purification to remove base metals (copper, nickel, zinc) and platinum group metals (PGMs). Techniques include:

Precipitation: Selective chemical precipitation (e.g., using sulfides or salts) to remove impurities.

Solvent Extraction: Using organic solvents to selectively transfer gold from the aqueous solution.

Ion Exchange: Passing the solution through resins that selectively adsorb gold ions.

5. Reduction & Precipitation

Purified gold solution is treated to recover solid gold. Common methods:

Chemical Reduction: Adding precipitating agents to produce fine gold powder.

Electrolytic Refining (Electrowinning): Passing electric current through the solution to deposit pure gold onto cathodes (often used after solvent extraction). This yields high-purity gold crystals or sludge.

6. Melting & Casting

The precipitated gold powder or cathode sludge is thoroughly washed, dried, and melted in a high-temperature furnace under a protective flux (e.g., borax) to remove any residual oxides. Molten gold is then cast into bars or granules of desired weights and purity (e.g., 999.9 fine gold).

7. Effluent Treatment & Recycling

Responsible refining mandates treating all waste streams (acidic liquors, wash waters) to neutralize pH, precipitate, and recover residual metals, ensuring environmental compliance. Water recycling is increasingly integrated.

Beyond the Basics: Modern Trends & Long-Term Value

Leading gold refining plant manufacturers focus on:

Automation & Digitalization

Automated gold refining systems with PLC controls enhance precision, safety, yield consistency, and data logging for traceability.

Sustainability & ESG

Solutions minimizing chemical consumption, energy use, and emissions are paramount. Look for closed-loop systems and eco-friendly gold refining technology.

Conflict-Free Sourcing

Ensuring your supply chain adheres to responsible sourcing standards (e.g., LBMA, RMI) is crucial. Reputable manufacturers support this through transparent processes and documentation.

Choosing Your Partner: Key Questions

When selecting a gold refining plant manufacturer, ask:

Can you provide references for plants processing similar feedstock to mine?

What are the guaranteed recovery rates and achievable purity levels?

How is environmental compliance integrated into the plant design?

What level of training and ongoing technical support do you offer?

Can you provide a detailed process flow diagram and mass balance?

Invest Wisely, Refine Successfully

Understanding the intricacies of the gold refinery process and partnering with an experienced, innovative gold refining plant manufacturer is not just an operational decision – it’s a strategic investment in the quality, profitability, and sustainability of your gold business. By prioritizing efficiency, purity, compliance, and modern technology, you secure a significant competitive edge in the global precious metals market.

Ready to explore the optimal gold refining solution for your specific needs? Request a detailed consultation and process overview today.