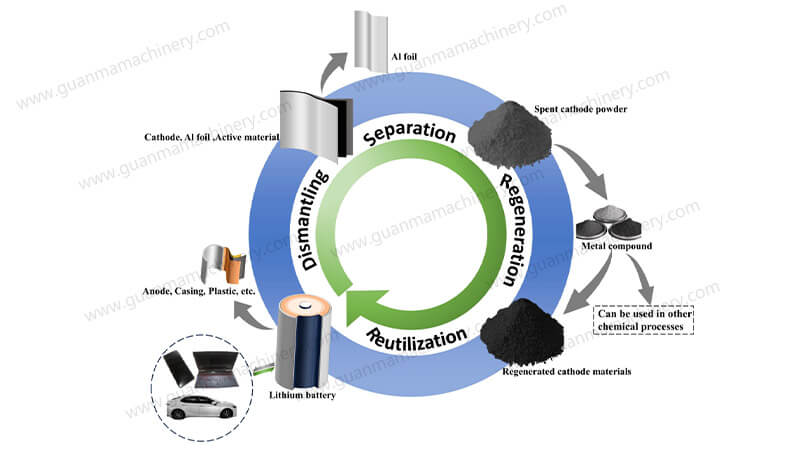

Guanma Machinery’s hydrometallurgy process battery recycling technology provides the answer – a closed-loop, high-efficiency system designed to recover >98% of critical metals from battery black mass. If you’re battling low recovery rates, environmental compliance hurdles, or inconsistent output quality, this detailed breakdown reveals why our hydrometallurgical processes for recycling spent lithium-ion batteries outperform traditional methods.

The Guanma Advantage: Precision Metal Liberation

Unlike pyrometallurgy (smelting) which loses lithium and generates emissions, our hydrometallurgy battery recycling process uses targeted chemical reactions in aqueous solutions to selectively extract metals. Here’s how our proprietary system works:

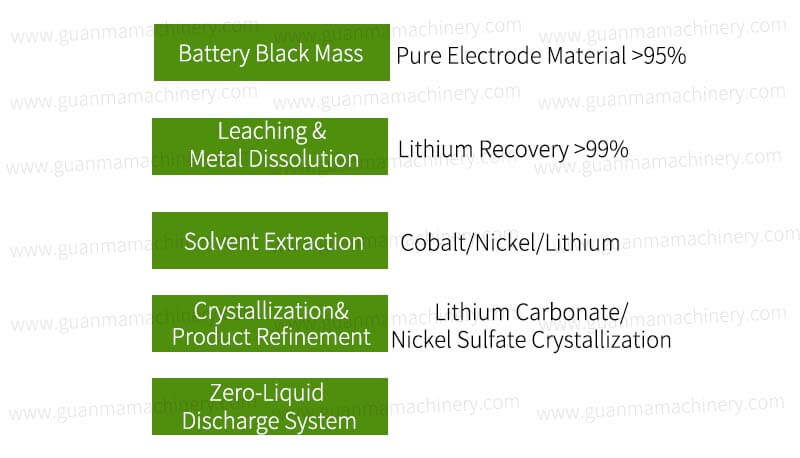

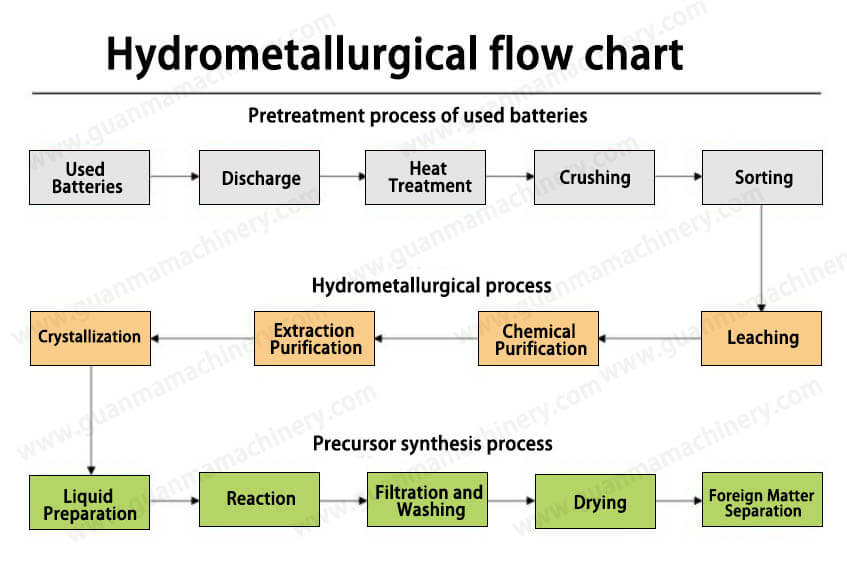

Step 1: Intelligent Black Mass Preparation

Our Black Mass Hydrometallurgy Machine integrates automated feeding and impurity removal

Precisely crushes and sieves material to optimal particle size (<200µm)

Removes plastics/aluminum foils via flotation, ensuring >95% pure electrode material

Key Benefit: Eliminates downstream contamination that disrupts chemical processes

Step 2: Targeted Leaching & Metal Dissolutio

Proprietary leaching reactors operate at controlled temperatures (60-90°C)

Customizable acid/oxidant blends (H₂SO₄/H₂O₂ or organic acids) dissolve metals

Real-time pH/ORP sensors optimize reaction kinetics

Key Innovation: Lithium recovery >99% (vs. <40% in smelting)

Step 3: Multi-Stage Solvent Extraction

Cascading mixer-settlers separate metals with surgical precision:

1. Extract cobalt

2. Separate nickel

3. Recover lithium

Automated reagent dosing maintains separation efficiency >99.5%

Competitive Edge: Achieves battery-grade sulfate purity (99.9%) in single pass

Step 4: Crystallization & Product Refinement

Lithium carbonate/nickel sulfate crystallization under vacuum

Cobalt oxalate precipitation with ammonium oxalate

Graphyte recovery via froth flotation from residue

Value Add: Directly produces saleable battery precursor materials

Step 5: Zero-Liquid Discharge System

Treats wastewater via reverse osmosis/evaporation

Recovers >95% process water for reuse

Solidifies residues into non-hazardous slag

Why Global Recyclers Choose Guanma’s Hydrometallurgy Process?

Feature | Traditional Methods | Guanma Solution

Lithium Recovery | <40% | >98%

Cobalt Purity | 95-97% | 99.95%

Chemical Consumption | High | 30-40% Lower

Carbon Footprint | 8-10 tCO₂/t Black Mass | <1.5 tCO₂/t

Our modular hydrometallurgical battery recycling plants deliver:

Higher Profits: $4,200+ value recovered per ton of NMC622 black mass

Faster ROI: Full-scale plant payback in 2.3 years (industry avg: 5+ yrs)

Unlock Your Battery Recycling Potential

Guanma Machinery’s end-to-end hydrometallurgy process battery recycling technology transforms black mass into high-purity cobalt sulfate, battery-grade lithium carbonate, and nickel cathode precursor – all within a single, environmentally compliant facility.

Ready to upgrade your recycling operations? Contact Guanma Machinery for your customized flow sheet and feasibility study. Let’s turn battery waste into your most profitable revenue stream!