The explosive growth in electric vehicles (EVs), consumer electronics, and renewable energy storage has created an urgent global challenge: what happens to lithium-ion batteries at the end of their life? Simply discarding them isn’t just wasteful – it’s environmentally hazardous and misses a massive opportunity. Lithium battery recycling solutions are no longer a niche concept; they are a critical necessity for sustainable business practices and resource security. If you’re seeking reliable, efficient, and profitable lithium-ion battery disposal methods, understanding the latest innovative lithium battery recycling technology is paramount.

The Imperative for Advanced Lithium Battery Recycling

Landfilling lithium batteries poses significant fire risks and leads to soil and groundwater contamination from heavy metals (like cobalt, nickel) and electrolytes. Incineration releases toxic fumes. Beyond the environmental toll, it represents a staggering loss of valuable, finite resources critical for manufacturing new batteries. Efficient lithium battery recycling solutions directly combat resource depletion, reduce reliance on volatile mining markets, lower the carbon footprint of new batteries, and ensure regulatory compliance in an increasingly strict global landscape.

How Modern Lithium Battery Recycling Solutions Work: A Closed-Loop Approach

Sophisticated lithium battery recycling solutions go far beyond simple crushing. Leading facilities employ a multi-stage, often automated process designed for maximum recovery and safety:

1. Safe Collection & Logistics

Secure transportation networks designed for hazardous materials, adhering to UN38.3 and other international regulations, are the essential first step in any sustainable battery recycling program.

2. Discharge & Dismantling

Batteries are fully discharged for safety. Automated or manual processes then remove casings, cables, and electronic control units (ECUs).

3. Mechanical Processing

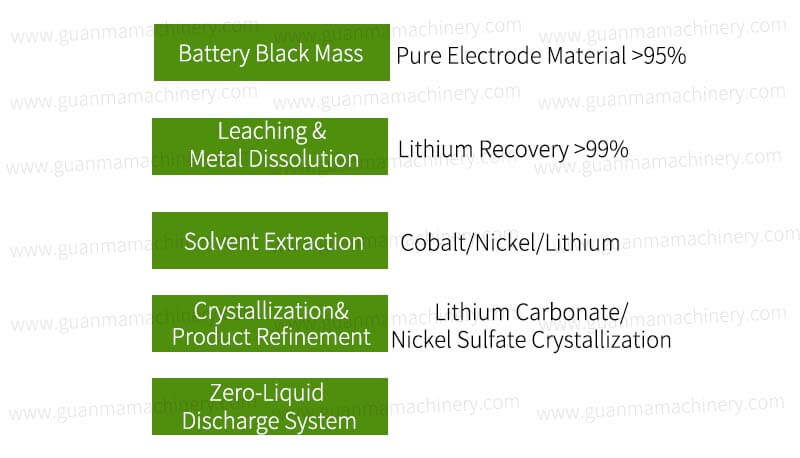

Batteries are shredded in an inert atmosphere (like nitrogen) to prevent fires/explosions. This produces “black mass” – a powder containing the valuable cathode and anode materials.

4. Advanced Separation & Hydrometallurgy

This is where innovative lithium battery recycling technology shines:

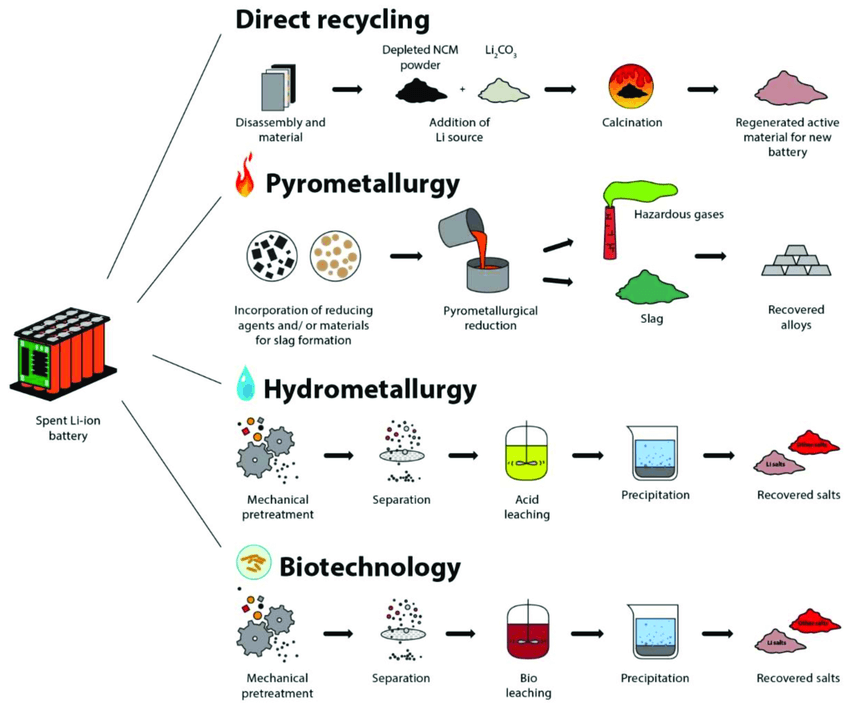

Hydrometallurgy

The dominant method. Black mass undergoes leaching using specific acids or bases to dissolve the metals. Sophisticated solvent extraction and precipitation techniques then separate and purify individual elements like lithium carbonate, cobalt sulfate, nickel sulfate, and manganese carbonate to battery-grade purity (>99.5%).

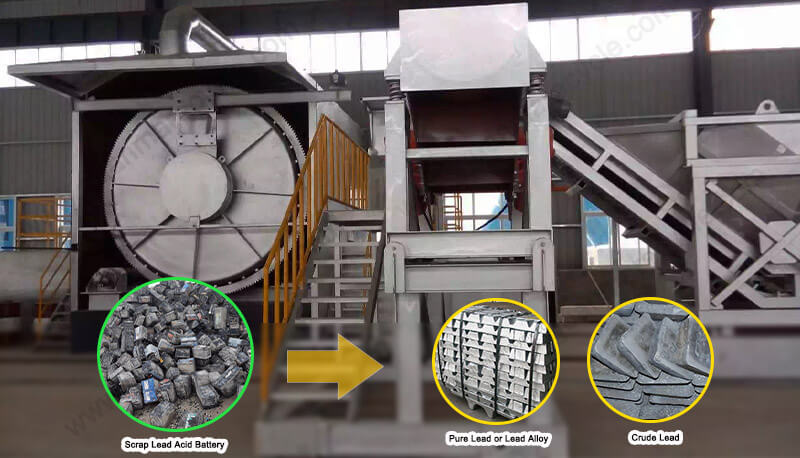

Pyrometallurgy (Smelting)

High-temperature processes recover cobalt, nickel, and copper into an alloy, with lithium often ending up in slag (though newer methods aim to recover it). Often used for mixed battery streams.

Direct Cathode Recycling

An emerging innovative lithium battery recycling technology focused on repairing and reusing the cathode material directly, minimizing chemical processing and energy use.

5. Purification & Refining

Recovered materials undergo further refining to meet the stringent specifications required by battery manufacturers for reuse in new batteries or other industries.

6. Residue Management

Any remaining plastics, electrolytes, or slags are treated or disposed of using eco-friendly battery disposal methods, ensuring minimal environmental impact.

Why Partner with a Specialist in Lithium Battery Recycling Solutions?

Maximize Resource Recovery

Access innovative lithium battery recycling technology achieving recovery rates exceeding 95% for key metals like cobalt, nickel, and copper, and >80% for lithium – turning waste into valuable feedstock.

Ensure Regulatory Compliance

Navigate complex international waste shipment and environmental regulations with confidence. Avoid costly fines and reputational damage.

Enhance ESG Credentials

Demonstrate a tangible commitment to environmental responsibility (E), ethical supply chains (S), and robust governance (G) through verifiable sustainable battery recycling programs.

Mitigate Supply Chain Risk

Securing secondary sources of critical battery materials through reliable lithium-ion battery disposal methods insulates your business from mining shortages and price volatility.

Reduce Environmental Liability

Ensure hazardous components are handled and neutralized using eco-friendly battery disposal methods, protecting the environment and your brand.

Applications: Who Needs Lithium Battery Recycling Solutions?

Electric Vehicle (EV) Manufacturers & OEMs

Managing end-of-life EV packs and production scrap responsibly is crucial.

Consumer Electronics Brands

Laptops, smartphones, tablets, power tools – all generate significant lithium battery waste.

Battery Manufacturers

Recycle production scrap efficiently and secure secondary raw materials.

Energy Storage System (ESS) Providers

Utility-scale and residential battery storage systems will eventually require recycling.

Waste Management & Recycling Companies

Expand service offerings with specialized lithium battery recycling solutions.

Retailers & Distributors

Offer responsible take-back programs for end-consumers.

Investing in Sustainability and Resource Security

Implementing robust lithium battery recycling solutions is an investment in both environmental stewardship and long-term business resilience. By recovering critical materials, you contribute directly to a circular economy for batteries, reducing the need for virgin mining and its associated impacts. This transition is fundamental to sustainable battery recycling programs that power our future responsibly.

Choose the Future of Battery Disposal

Don’t let valuable resources go to waste or risk environmental harm. Partner with a leader in innovative lithium battery recycling technology. We provide comprehensive, global lithium battery recycling solutions, from secure international collection logistics to advanced processing using eco-friendly battery disposal methods, delivering high-purity materials back into the supply chain.

Contact us today to discuss how our tailored lithium battery recycling solutions can solve your end-of-life battery challenges, recover maximum value, and strengthen your sustainability profile.