Investing in a lithium ion battery recycling machine unlocks high-value materials from discarded EV batteries, consumer electronics, and industrial energy storage.

Lithium ion battery recycling machine can process raw materials

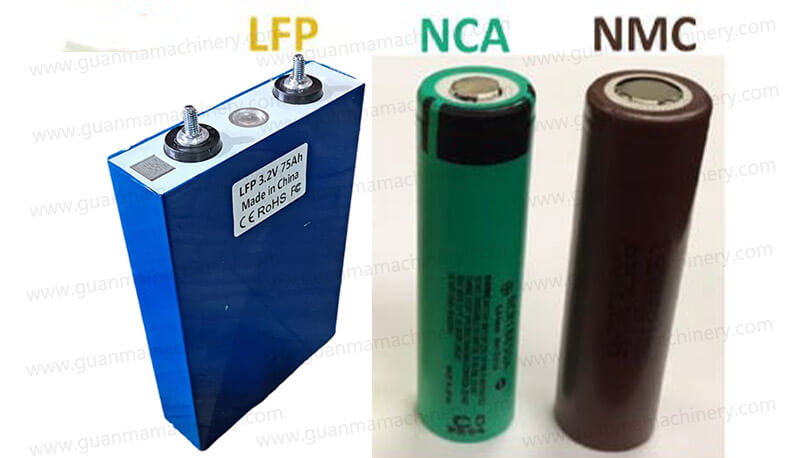

A lithium ion battery recycling plant handles:

EV battery packs (NMC, LFP, LCO chemistries)

Portable electronics (smartphone/laptop batteries)

Industrial ESS units (scaled from 1kWh to 1MWh)

Critical prep: Batteries must be discharged to <1.5V and shredded under inert gas to prevent thermal runaway.

Daily Processing Capacity & Output (Focus on practical solutions)

| Plant Scale | Input Capacity | Output per Day |

| Small-scale | 1-3 tons | 500kg black mass, 200kg copper foil |

| Medium-scale | 5-10 tons | 2.5 tons black mass, 1t plastics |

| Industrial | 20-50+ tons | 12t black mass, 4t aluminum casings |

Black mass contains 15-25% lithium, 5-15% cobalt, 10-20% nickel.

Lithium Ion Battery Recycling Machine Step-by-Step Recycling Process

1. Shredding & Separation

Batteries crushed in nitrogen atmosphere

Vibrating screens separate:

Plastics (15-20% of weight)

Copper/aluminum foil (5-10%)

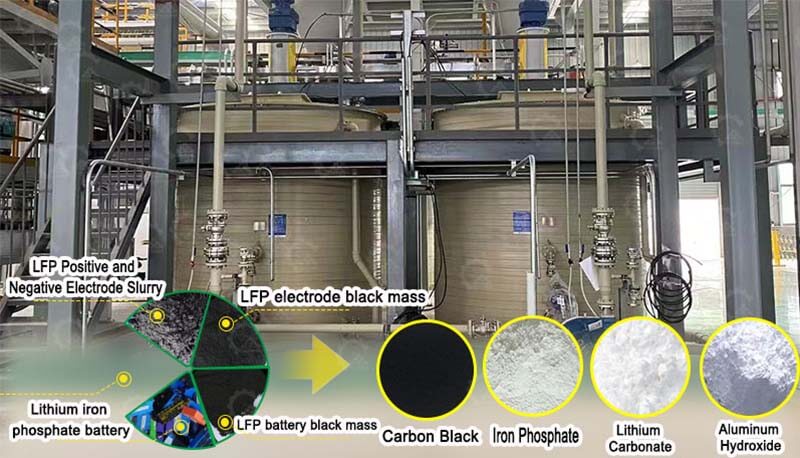

Electrode powder (“black mass”, 60-70%)

2. Hydrometallurgical Processing

Black mass leached with H₂SO₄/H₂O₂

Solvent extraction isolates:

Lithium carbonate (99.5% purity)

Cobalt sulfate (battery-grade)

Nickel sulfate (EV cathode-ready)

3. Pyrometallurgical Option

Smelting at 1400°C recovers cobalt/nickel alloy

Slag contains lithium (requires secondary processing)

Equipment Investment Breakdown (This data is for reference only)

| Component | Function | Cost Range |

| Discharge system | Depletes residual charge | $80,000-$150,000 | (This data is for reference only)

| Inert-gas shredder | Safe size reduction | $250,000-$500,000 | (This data is for reference only)

| Hydrometallurgical unit | Metal extraction | $1M-$2.5M |(This data is for reference only)

| Emission controls | NFPA compliance | $300,000-$700,000 | (This data is for reference only)

Total setup cost: $1.5M-$4M for 5-10t/day plant(This data is for reference only).

Profitability Analysis

Revenue streams from 1 ton of Li-ion batteries:

Black mass (600kg): $1,800-$3,000 (at $3-5/kg)(This data is for reference only)

Copper foil (50kg): $500 (at $10/kg)(This data is for reference only)

Aluminum (100kg): $250 (at $2.5/kg)(This data is for reference only)

Plastics (150kg): $75 (at $0.5/kg)(This data is for reference only)

Total revenue: $2,625-$3,825/ton (This data is for reference only)

Operating costs: $800-$1,200/ton (This data is for reference only)

Net profit: $1,400-$3,000/ton(This data is for reference only)

Maximizing ROI: Critical Success Factors

1. Feedstock sourcing

Partner with EV dismantlers/e-waste collectors

Offer $150-$300/ton for spent batteries

2. Product marketing

Sell black mass to refineries

Lithium carbonate to battery manufacturers

3. Regulatory compliance

Implement environmental management

Why Choose Turnkey Solutions?

Guanma Machinery lithium battery recycling equipment suppliers provide:

Process customization: NMC vs. LFP battery handling

Automation: AI-driven sorting (95% purity)

Byproduct monetization: Fluorine recovery from electrolyte

A lithium ion battery recycling machine setup delivers 35-50% ROI within 3 years by recovering critical minerals from the 2.5 million tons of Li-ion waste generated annually.