Solar Panel Recycling Machine in China: Your Complete Solution for Raw Material Processing, Capacity & Output

Struggling with the growing mountain of end-of-life solar panels? Finding efficient, profitable, and compliant recycling solutions is critical. Solar panel recycling machine in China offer advanced technology to transform this e-waste challenge into a sustainable revenue stream.

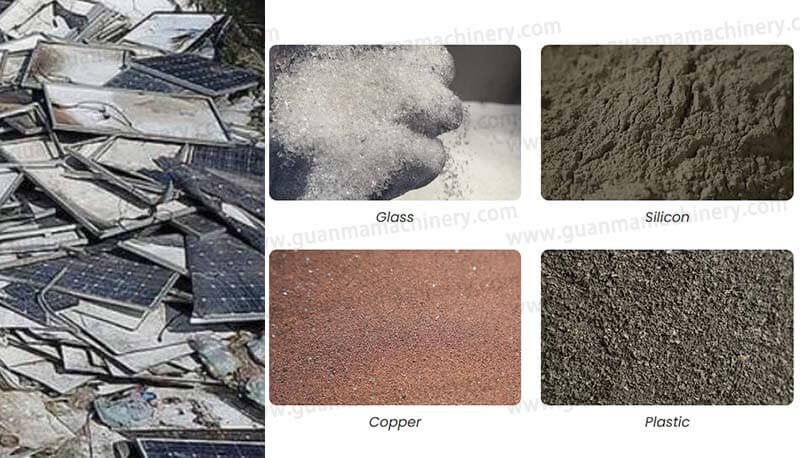

Understanding Your Input: What Raw Materials Can You Process

Whole End-of-Life (EoL) Panels: Machines are designed to handle entire photovoltaic (PV) modules – crystalline silicon (c-Si) dominate the market, but many systems also process thin-film (CdTe, CIGS).

Panel Components: Systems efficiently separate and process:

Tempered Glass (70-75% of weight)

Aluminum Frames

Copper Wiring & Junction Boxes

Silicon Solar Cells (often containing silver contacts)

Polymer Backsheets (Tedlar/PET/EVA)

Encapsulants (EVA, POE)

Pre-Processed Fractions: Some machines accept pre-shredded material or specific separated components for further refinement.

Meeting Your Scale: Daily Processing Capacity Explained

Chinese solar panel recycling equipment comes in various sizes to match your operational volume and investment level. Capacity is typically measured in metric tons per day (T/D) or panels per day:

1. Small-Scale Systems (Pilot/Regional)

1-3 T/D (approx. 50-150 panels/day). Ideal for initial market entry or localized collection points.

2. Medium-Scale Systems (Most Common)

5-15 T/D (approx. 250-750 panels/day). Suits established recyclers handling regional or national volumes. Offers the best balance of investment and output for many businesses.

3. Large-Scale Industrial Systems

20+ T/D (1000+ panels/day). Designed for high-volume national processors or dedicated recycling facilities. Features maximum automation.

Capacity Comparison Table

Capacity Tier | Metric Tons/Day | Approx. Panels/Day | Ideal For|

Small-Scale | 1 – 3 | 50 – 150 | Pilots, Local Collectors |

Medium-Scale | 5 – 15 | 250 – 750 | Regional/National Recyclers |

Large-Scale | 20+ | 1000+ | High-Volume Facilities |

Delivering Tangible Value: What Are the Final Recycled Products?

The goal of a turnkey PV recycling solution in China is high-purity output streams ready for resale:

1. High-Purity Glass Cullet (95-98% purity)

Suitable for insulation fiberglass, foam glass, sandblasting media, or new glass production. The largest volume output.

2. Refined Metals

Aluminum Frames: Clean, separated metal ready for smelting.

Copper Wires/Contacts: High-value recovered copper.

Silver (from cells): Extracted via specialized processes (hydrometallurgy/pyrometallurgy) in advanced lines.

3. Silicon Powder/Silicon Wafers

Recovered silicon can be purified for reuse in new panels or other industries (metallurgical grade).

4. Plastic/Polymer Flakes

Primarily from backsheets and junction boxes. Can be used in lower-grade plastic products or energy recovery (where permitted).

5. Clean Solar Cells

Sometimes recovered intact for potential reuse in secondary markets (requires careful testing).

Why Choose Chinese Solar Recycling Machinery?

Beyond core functionality, leading Chinese solar panel recycling machine manufacturers offer distinct advantages:

Cost-Effectiveness

Significant savings compared to European/North American alternatives without sacrificing core efficiency.

Advanced Technology

Incorporating automation, AI-powered sorting, and efficient separation techniques (mechanical, thermal, chemical).

Scalability & Customization

Solutions tailored precisely to your input mix and desired output quality.

Compliance Focus

Machines designed to meet stringent international (WEEE) and evolving Chinese environmental standards (GB standards).

Strong Supply Chain

Access to robust manufacturing capabilities ensures faster production and parts availability.

Maximize Your ROI with China’s E-Waste Recycling Technology

Investing in a solar panel recycling machine in China isn’t just about disposal; it’s about unlocking the resource value trapped in end-of-life PV modules. By understanding the raw materials processed, selecting the right daily capacity for your needs, and knowing the high-value recycled products generated, you can build a profitable and sustainable recycling business.

Ready to transform solar panel waste into valuable resources? Contact leading Chinese solar panel recycling equipment suppliers today for a customized solution and quote!

Popular Questions:

Q: What types of solar panels can Chinese recycling machines handle?

A: Primarily crystalline silicon (mono & poly), increasingly thin-film (CdTe, CIGS). Specify your target feedstock.

Q: What purity levels can I expect for recycled glass and metals?

A: Advanced lines achieve 95-98%+ glass purity and high-grade separated metals (Al, Cu). Silver recovery requires specific modules.

Q: How automated are Chinese solar recycling lines?

A: Ranges from semi-automatic (medium-capacity) to fully automatic (large-scale). Automation levels impact labor costs and throughput.

Q: Do Chinese manufacturers offer installation and training?

A: Reputable suppliers provide comprehensive services: installation, commissioning, operator training, and technical support.

Q: What are the key environmental compliance considerations?

A: Ensure the process safely handles hazardous dust (silica), gases (from thermal steps), and recovers valuable materials efficiently to minimize landfill. Ask about emissions control systems. Compliance with GB standards and international norms is crucial.