Lead-acid batteries power everything from cars to industrial equipment, but their disposal poses significant environmental risks. Proper recycling is critical to prevent toxic lead and sulfuric acid from contaminating soil and water. Lead battery recycling plant transforms used batteries into reusable materials while adhering to global environmental standards.

Why Lead-Acid Battery Recycling Matters

Over 99% of lead-acid batteries are recyclable, making them one of the most sustainable energy storage solutions. However, improper disposal releases hazardous substances like lead, plastic, and acid into ecosystems. A professional lead acid battery recycling plant ensures:

Toxic waste prevention

Resource recovery (lead, plastic, electrolytes)

Reduced mining demand for raw materials

For businesses managing used batteries, partnering with a certified recycling facility is both an ethical obligation and a cost-effective strategy.

Step-by-Step Lead-Acid Battery Recycling Process

1. Battery Collection & Transportation

Recycling begins with safe collection. Authorized recyclers use specialized containers to transport used batteries to the recycling plant, minimizing leakage risks. Industrial clients often benefit from scheduled pickups to streamline logistics.

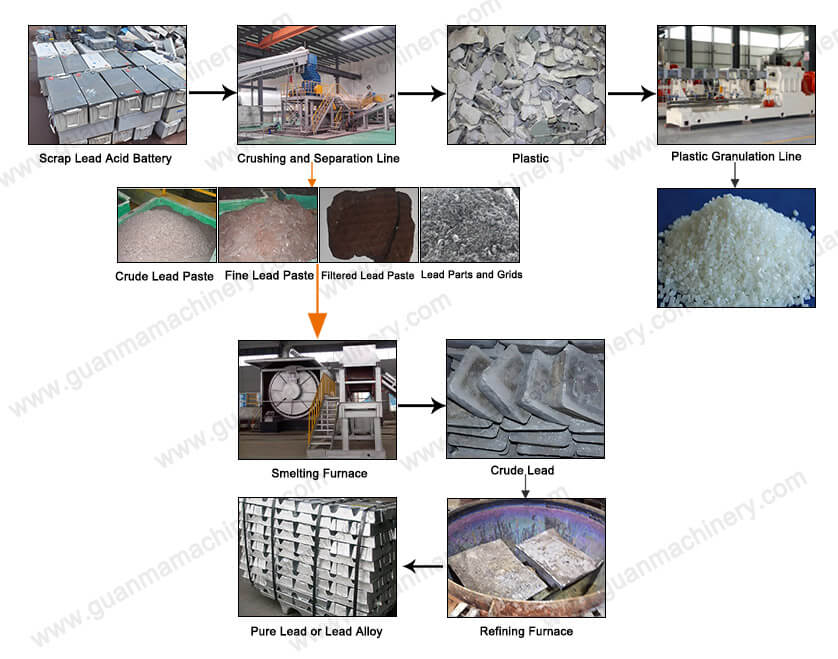

2. Battery Breaking & Separation

At the plant, batteries undergo mechanical shredding. Advanced systems separate components into three streams:

Lead plates/grids (44–60% of battery weight)

Polypropylene plastic casings(22–30%)

Sulfuric acid electrolyte (10–16%)

This step employs enclosed systems to capture dust and fumes, ensuring worker safety and environmental protection.

3. Neutralizing Sulfuric Acid

The electrolyte is processed in two ways:

Conversion to sodium sulfate (used in detergents or textiles)

Reclamation into purified acid for reuse in new batteries

Modern plants neutralize acid without releasing harmful emissions, aligning with zero-waste goals.

4. Lead Smelting & Refining

Lead components are melted in high-temperature furnaces. Impurities (e.g., dirt, oxides) are removed, producing 99.9% pure lead ingots. Advanced plants use hydrometallurgical processes to reduce energy use and emissions by up to 40% compared to traditional smelting.

5. Plastic Recycling

Battery casings are washed, melted, and pelletized to create raw materials for new battery cases or industrial products.

6. Quality Control & Distribution

Recycled lead, plastic, and byproducts undergo rigorous testing before being sold to battery manufacturers, reducing reliance on virgin materials.

Advantages of Partnering with a Certified Recycling Plant

1. Regulatory Compliance

Certified plants follow protocols like ISO 14001 and OHSAS 18001, ensuring adherence to international environmental and safety standards.

2. Cost Savings

Recycled lead is 30–40% cheaper than mined lead, lowering production costs for battery makers.

3. Carbon Footprint Reduction

Recycling lead uses 35–40% less energy than primary production, slashing greenhouse gas emissions.

4. Circular Economy Contribution

Closed-loop recycling keeps 90%+ of battery materials in use, supporting sustainable industries.

How to Choose a Lead-Acid Battery Recycling Partner

When selecting a lead acid battery recycling plant, verify:

Certifications (e.g., ISO)

Transparency in process documentation

Global shipping capabilities for international clients

Tailored solutions for bulk battery disposal

Understanding the lead-acid battery recycling process is essential for businesses seeking eco-friendly disposal solutions. A certified lead acid battery recycling plant not only safeguards the environment but also unlocks economic value from used batteries. By prioritizing sustainable partnerships, industries can drive the transition toward a circular economy while adhering to global environmental mandates.